PVC Compound Factory

- Home

- PVC Compound Factory

- Department Introduction

Department Introduction

Professional R&D team: create high-quality rubber products that meet your requirements

Our experienced professional R&D personnel focus on the development and manufacturing of various functional colloidal particles, ranging from temperature resistance, cold resistance, flame retardant, mildew resistance, antibacterial, environmental protection, UV resistance to hardness and other properties, our technical R&D team can According to the unique needs of customers, we tailor-make rubber granule products that meet your needs.

YI-CHEN SHIN YEH plastic granulation factory has rich manufacturing experience and advanced production equipment to provide customers with high-quality and reliable rubber granulation solutions. We are committed to professional and customized services. Whether in the early stages of product development or later adjustments, we are able to provide immediate professional advice and support. Let our team bring value to your business and meet your unique rubber pellet needs.

YI-CHEN SHIN YEH plastic granulation factory, your trustworthy rubber granulation solution expert!

YI-CHEN SHIN YEH : PVC plastic pellet manufacturer guaranteed by excellent technology to meet diverse needs

YI-CHEN SHIN YEH 's plastic granulation factory is a professional manufacturer of PVC plastic granules. We have Lina Machinery which is suitable for mixing, kneading and blending of ingredients in various rubber, plastic and chemical industries. Lina Machinery ensures good dispersion and uniformity of the product with its special design and manufacturing process. Automated production, high productivity and stable quality are the advantages of Lina Machinery. We use this kind of machinery to produce high-quality soft PVC plastic.

With our superior manufacturing technology and expertise, we are committed to providing our customers with the highest quality PVC plastic products. We are well aware of the market's demand for quality and consistency, so through the application of Lina machinery, we ensure that the product reaches the best state in terms of dispersion and uniformity.

A powerful tool for plastic modification: twin-screw extruder with flexible mixing and low energy consumption

The twin-screw extruder has good mixing and plasticizing capabilities. It is suitable for plastic modification with large output, fast extrusion speed, and low energy consumption per unit output. It has characteristics such as good mixing performance, high production and processing flexibility, and basic processing technology. Parameter controllability, high efficiency, higher economy, mainly producing rigid PVC plastic.

Flexible production of soft and rigid PVC: multiple applications of single-screw extruders

Single-screw extruders are mainly used for the extrusion of pipes, sheets, plates, and special profiles. They are also used for granulating some modified materials. Both soft and hard PVC plastics are produced individually on independent machines.

A powerful tool for molding processing: high-speed mixer accurately mixes various polymers

During the polymer molding process, the high-speed mixer usually performs batching operations, that is, mixing various components together to form a uniform system as much as possible. It mainly consists of a cylindrical mixing chamber and a high-speed mixer installed at the bottom of the mixing chamber. Composed of rotating impeller. It is suitable for solid mixing and solid-liquid mixing, and is more suitable for preparing powder.

PRODUCTS

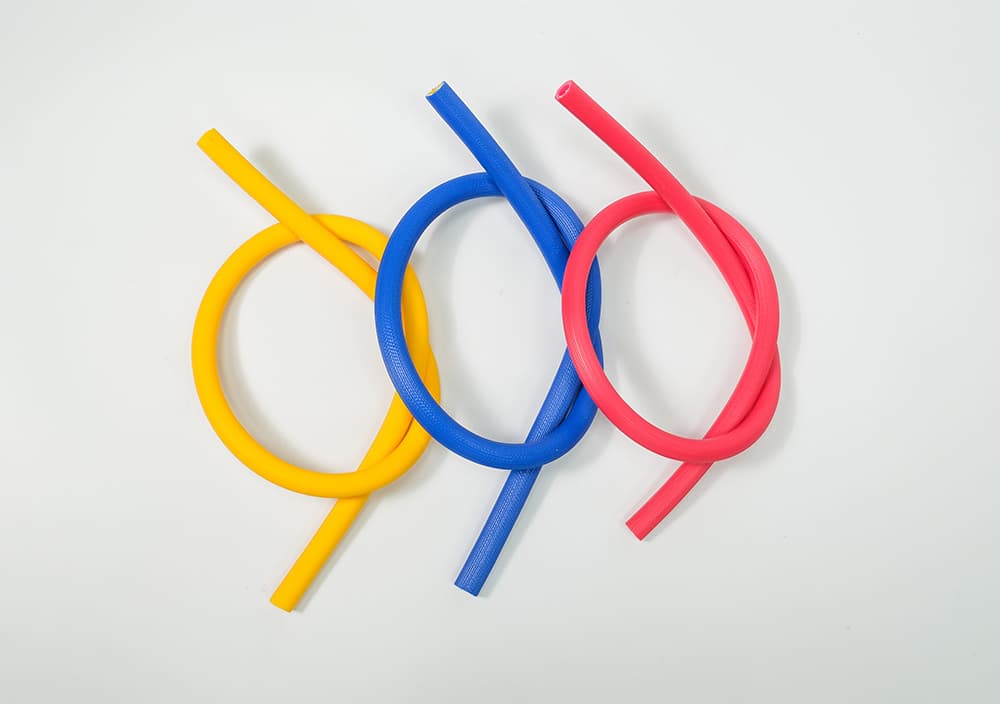

Spinning Yarn Application

Environmentally Friendly Material Application

Extrusion Molding Applications

Injection Molding Applications

EQUIPMENT

Specific Gravity Libra

Weigh the weight of the sample in air and liquid (water), and calculate the specific gravity to determine the basic physical properties of the product.

Tensile Testing Machine

Tensile and compression failure tests, tearing, peeling and compression tests.

Ventilation Aging Testing Machine

The ventilated aging testing machine tests the thermal aging properties of rubber, plastics and various insulating materials to ensure that it meets customer needs.

Hot Air Circulation Oven

Capacity: 150 L

MI Melt Index Meter

The timing measurement method is used to measure the rate at which molten plastic extrudes through a fine hole mold of a specified length, which is used to determine the extrusion rate of the polymer flow rate during the process.

Film Laminating Press

The test piece forming machine for plastic and various polymer experiments uses high temperature and pressure to mold the raw materials into the required test piece shape with different molds to facilitate subsequent quality inspection.